CNC Machining, Welding, injection Molding & Powder Coating

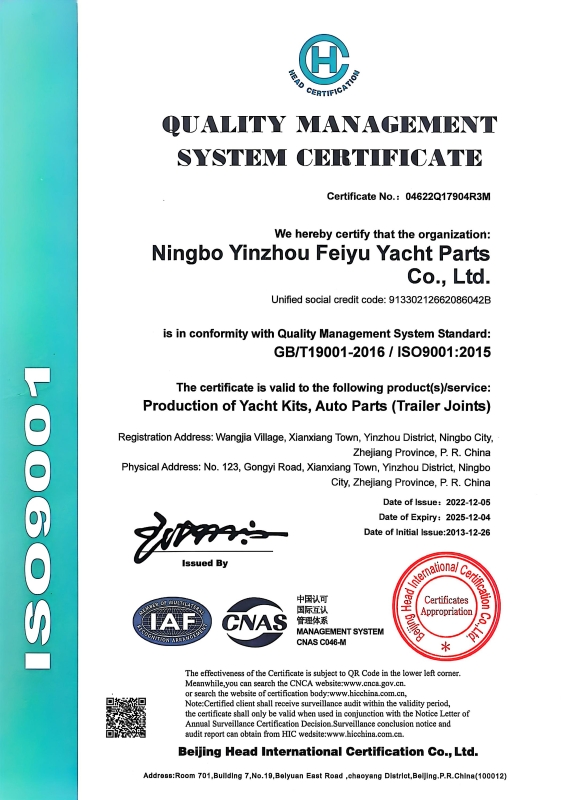

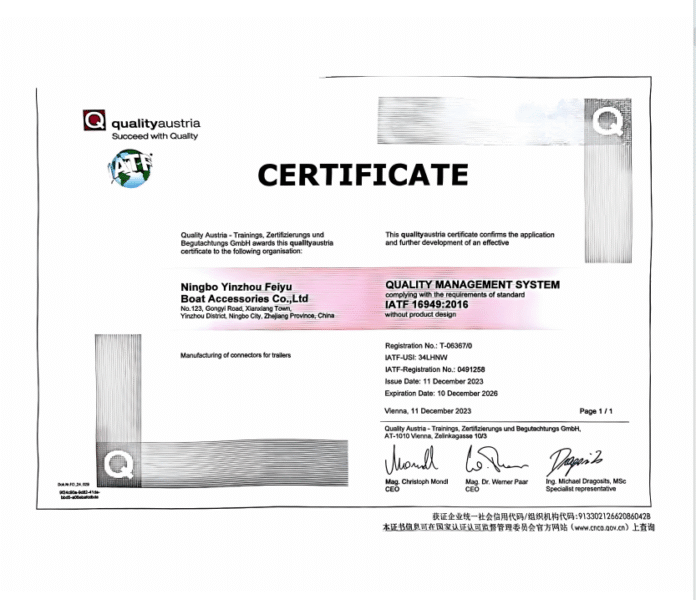

ISO 9001 / IATF 16949 Certified OEM Manufacturer

Main Custom Parts Display

High-Precision Components from Prototyping to Full-Scale Production

Precision Manufacturing Processes | Custom Engineering Solutions

22+ Advanced Technologies, End-to-End Production Control

CNC Machining

CNC Machining is a computer-controlled subtractive manufacturing technique where material is precisely removed from a workpiece based on digital instructions (G-code) derived directly from CAD models. This process automatically shapes complex components with exceptional dimensional accuracy, tight tolerances, high repeatability, and superior surface finishes for aerospace, automotive, and medical applications.

Plastic Injection Molding

Plastic injection molding melts plastic resin, injects it under high pressure into mold cavities, cools it, then ejects the hardened part. This dominant manufacturing process efficiently produces large quantities of complex, high-precision plastic parts cost-effectively. It’s essential across automotive, medical, electronics, packaging, and industrial components industries.

Gravity Casting

Gravity casting, a permanent mold casting process, pours molten metal solely by gravity into durable, reusable molds. This key manufacturing technique efficiently produces intricate metal parts with enhanced structural integrity, finer grain structure, improved surface finish, and higher dimensional accuracy vs. sand casting. Widely used for engine blocks, wheels, and structural components.

Aluminum Profile extrusion

Aluminum profile extrusion heats aluminum billets, forces them through a shaped die, and cools the output. This efficient manufacturing process produces continuous, complex cross-section profiles with high strength-to-weight ratios. Essential for construction, automotive, electronics, solar framing, and industrial machinery, it offers design flexibility and mass production efficiency.

Metal Stamping

Metal stamping is a fabrication process transforming flat metal sheets into precise shapes using dies and presses. Key operations include blanking, punching, bending, and piercing. This highly automated, high-volume method delivers tight tolerances, complex geometries, and material efficiency for automotive, aerospace, appliances, and electronics components.

Laser Cutting

Laser Cutting is a non-contact thermal machining process where a high-energy focused laser beam melts, vaporizes, or burns material to create complex geometries with extreme precision. Controlled by digital programs (e.g., CNC G-code), it achieves narrow kerf widths, minimal thermal distortion, smooth edges, and low contamination, ideal for sheet metal, plastics, textiles, and semiconductors.

Robotic Welding

Robotic welding automates metal joining using programmable robotic arms with welding torches. This advanced manufacturing process delivers superior precision, increased productivity, and consistent quality for high-volume or complex repetitive welding tasks. It’s vital in automotive, aerospace, shipbuilding, construction, and industrial machinery fabrication, optimizing efficiency and safety.

Surface Finishings

Surface finishing improves metal appearance and provides crucial protection against damage, corrosion, and environmental factors. Common techniques include anodizing, protective coatings, spray painting, and electroplating—each enhancing durability and functionality.

Assembly line

Assembly line is a manufacturing process in which a product is assembled in a step-by-step sequence as it moves along a conveyor or workstation path. Each station performs a specific task, allowing for efficient mass production, reduced labor costs, and consistent product quality.

Transparent Manufacturing Workflow | Real-Time Progress Tracking

Co-Creating Your Market Leadership: Patentable DFMA Solutions + Exclusive Production Line Allocation

Quote

Request

We will execute a non-disclosure agreement to ensure your design and intellectual property remain fully protected.

Quotation & Optimization

We will provide a detailed offer price and simultaneously optimize both the design and manufacturing process—leveraging material and process alternatives to deliver up to 15% cost savings.

Order

Confirmation

Once your official purchase order is received, a 50% deposit will be required to secure production scheduling.

Prototype Development

Our team will produce a sample, complete with a comprehensive 3D report and necessary laboratory tests, and then submit it for your approval before moving forward.

Mass Production

During bulk manufacturing, you will receive daily progress updates and our quality-control checkpoints will ensure consistent adherence to specifications.

Delivery

We offer flexible shipping and logistics solutions, including EXW, FOB, and DDP options, along with full support for customs clearance.

After-Sales Service

Following delivery, we offer a two-year warranty that includes free maintenance and ongoing technical troubleshooting to keep your product performing optimally.

Advanced Manufacturing Center

Overview

Ningbo Yinzhou Feiyu Boat Accessories Co., Ltd is an OEM manufacturer with over 23 years of experience since its founding in 2001. We are certified to ISO 9001 and IATF 16949 standards.

Strategic Location

Headquartered near Beilun Port, Ningbo, our 40,000㎡ facility benefits from direct access to deepwater shipping routes for efficient global logistics.

Advanced Equipment

Our production is supported by German-Japanese CNC machining centers, 12,000W laser cutting systems, and robotic welding cells, ensuring high precision and reliability.

Vertical Integration

We offer complete in-house processes—from raw material processing to machining and surface treatment—all under IATF 16949-certified workflows.

Quality–Assurance

Full-Process Quality Control

Contact Us

Ready to transform your vision into reality? Our team of experts is just one message away from turning your ideas into life.

- (562) 588-1520

- info@nbfeiyu.com

- No.123 Gongyi Road, Xianxiang Town, Yinzhou District, Ningbo city, Zhejiang,China,315141

Custom Solutions

Tailored solutions based on your specific needs.

Fast Response

Respond within 24 hours to ensure smooth project progress.

24/7 Support

Always here to support you.